|

Paper Converting |

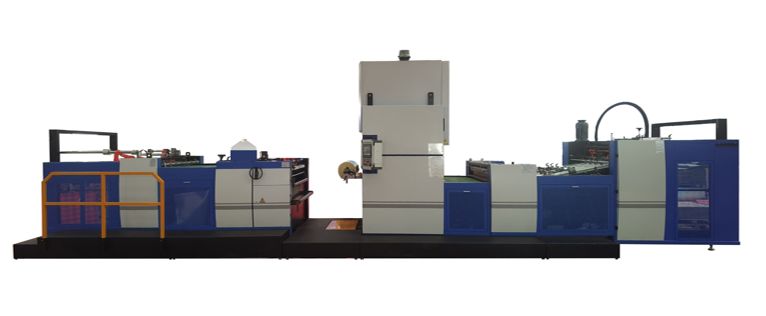

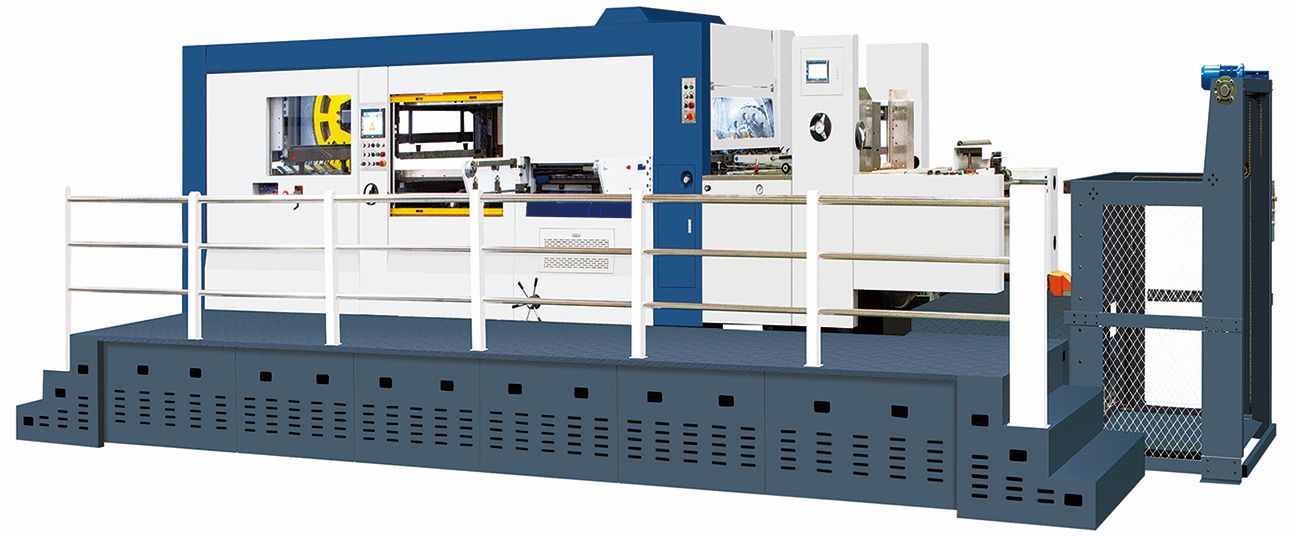

KMK Printing & Packaging Machinery, KMK ZLFM-1080MCW, 2025 (Ref.:M6220)

Year: 2025

Price: on request

Basic Configuration:

1. Automatic feeder: sheet-fed, Shaftless servo motor feeder, 8 suction nozzles

achieve high speed and high precision, to ensure that paper is continuously fed

into the machine. Non-stop feeder, Standard configuration with pre-stack unit.

Suction device guarantees stability and smooth of paper sending.

2. Powder remove calender: heating roller with scraper effectively clean the powder

and dust in the surface of paper. Improve the brightness after laminating.

3. Water based glue coating unit: roller coat, Coating glue on the sheets.

4. IR dryer: Using infrared lamp heating, high efficiency and energy saving hot air

circulation drying channel.

5. Lamination main unit: Multi purpose f

film laminating/ window film laminating

lamination heating pressing cylinder: The machine equipped with separate

circulating temperature controller besid

heating. energy saving. environmental pr |

|

|

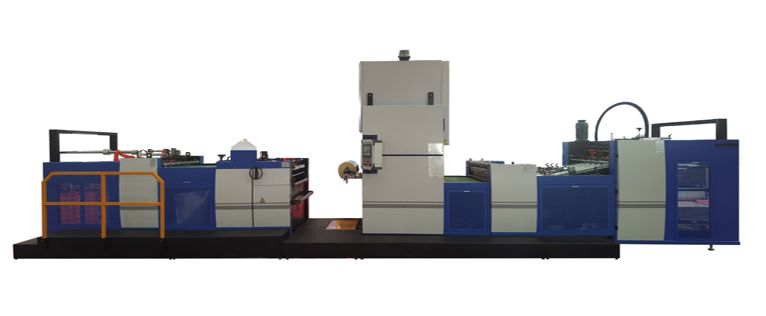

KMK Printing & Packaging Machinery, KMK ZLFM-1080SJR, 2025 (Ref.:M6221)

Year: 2025

Price: on request

Non-stop Feeder

Non-stop Stacker

Hot knife cutter & disc cutter

Mold temperature controller

Thin paper anti curling

Front lay

Sheets drawing

Optional:

- Chain knife cutting system

- Double lamination, Embossing unit

- UV enhancement unit

- Powder cleaning device

Youtube-Video Link: https://youtu.be/kKX |

|

|

KMK Printing & Packaging Machinery, KMK ZLFM-1080LCR, 2025 (Ref.:M6222)

Year: 2025

Price: on request

Max. speed 100 m/min, 40-70 kWh

With latest laminating technology

Beyond film covering technology

1 to 2 people to operate

Basic Configuration:

Automatic feeder: sheet-fed, Shaftless servo motor feeder, 8 suction nozzles achieve high speed and

high precision, to ensure that paper is continuously fed into the machine. Non-stop feeder, Standard

configuration with pre-stack unit. Suction device guarantees stability and smooth of paper sending.

Powder remove calender: heating roller with scraper effectively clean the powder and dust in the

surface of paper. Improve the brightness

Lamination main unit: Multi purpose for

Glue Coating and drying cylinder, lamination heating pressing cylinder: The machine equipped with

separate circulating temperature control

energy saving. environmental protection. |

|

|

|

|

KMK Printing & Packaging Machinery, KMK ZLFM-1080LC, 2025 (Ref.:M6293)

Year: 2025

Price: on request

Max. speed 100 m/min, 40-70 kWh

With latest laminating technology

Beyond film covering technology

1 to 2 people to operate

Basic Configuration:

Automatic feeder: sheet-fed, Shaftless servo motor feeder, 8 suction nozzles achieve high speed and

high precision, to ensure that paper is continuously fed into the machine. Non-stop feeder, Standard

configuration with pre-stack unit. Suction device guarantees stability and smooth of paper sending.

Powder remove calender: heating roller with scraper effectively clean the powder and dust in the

surface of paper. Improve the brightness

Lamination main unit: Multi purpose for

Glue Coating and drying cylinder, lamination heating pressing cylinder: The machine equipped with

separate circulating temperature control

energy saving. environmental protection. |

|

|

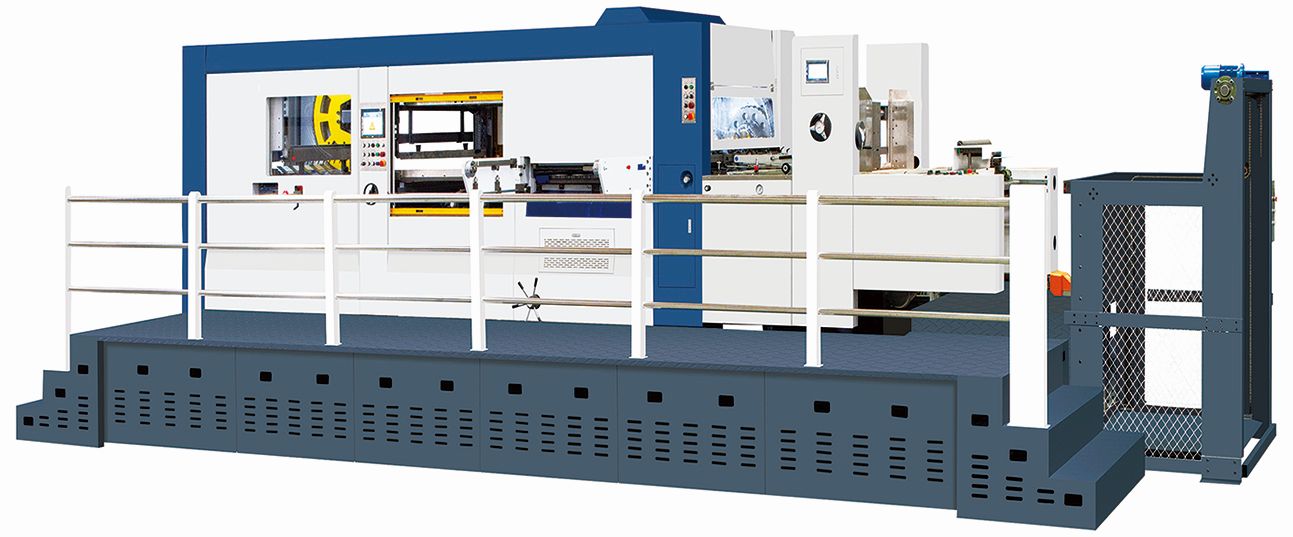

KMK Printing & Packaging Machinery, KMK ZLFM-1080MC, 2025 (Ref.:M6292)

Year: 2025

Price: on request

Basic Configuration:

1. Automatic feeder: sheet-fed, Shaftless servo motor feeder, 8 suction nozzles

achieve high speed and high precision, to ensure that paper is continuously fed

into the machine. Non-stop feeder, Standard configuration with pre-stack unit.

Suction device guarantees stability and smooth of paper sending.

2. Powder remove calender: heating roller with scraper effectively clean the powder

and dust in the surface of paper. Improve the brightness after laminating.

3. Water based glue coating unit: roller coat, Coating glue on the sheets.

4. IR dryer: Using infrared lamp heating, high efficiency and energy saving hot air

circulation drying channel.

5. Lamination main unit: Multi purpose f

film laminating/ window film laminating

lamination heating pressing cylinder: The machine equipped with separate

circulating temperature controller besid

heating. energy saving. environmental pr |

|

|

KMK Printing & Packaging Machinery, KMK RFM-106MC, 2024 (Ref.:M5588)

Year: 2024 Size: 1060 × 1100mm

Price: on request

Max. sheet size: W1060×L1100mm

Min. sheet size: W320×L300mm

Max. mechanical speed: 100m/min, 11000sheets/hour

Laminating speed: 20-100m/min

Paper thickness: 105-500gsm

Piling height: 1300mm

Stacker piling height: 1300mm

Total power: 78kW (380V, AC3f, 50Hz) (normal working

power: 28-38kW)

Overall dimension: L 11277 × W 2510 × H 3030 mm

https://www.youtube.com/watch?v=TPqhpGp3 |

|

|

KMK Printing & Packaging Machinery, KMK HT-760P, 2024 (Ref.:M5378)

Year: 2024 Size: 760 x 520 mm

Price: on request

Max. cutting size: 760 x 520 mm

Min. cutting size: 320 x 260 mm

Max. pressure: 250 Tons

Thickness of corrugated paper: 80g/m to E flute corrugated paper =4mm

Die-cutting precision: ±0.075mm

Max Feeding Pile Height: 1280 mm

Max Delivery Pile Height: 1160mm

Max. speed: 9.000 sheets/hour

Max. die cutting and stripping speed: 9.000 sheets / hour

Video link: https://youtu.be/DAAeRV-YKDY |

|

|

KMK Printing & Packaging Machinery, KMK XY-2600, 2024 (Ref.:M6299)

Year: 2024 Size: 420 x 2600 mm

Price: on request

Technological Parameter:

Sticky box:

Max. paper size (A+B) *2 (mm): 2600

Min. paper size (A+B) *2 (mm): 420

Max. carton length A (mm): 900

Min. carton length A (mm): 130

Max. carton width B (mm): 650

Min. carton width B (mm): 80

Max. paper height (C+D+C) (mm): 1200

Min. paper height (C+D+C) (mm): 170

Max. cap size C (mm): 350

Min. cap size C (mm): 50

The minimum height D (mm): 100 |

|

|

|

|

KMK Printing & Packaging Machinery, KMK HT-1050A, 2024 (Ref.:M5379)

Year: 2024 Size: 730 x 1040 mm

Price: on request

Max. cutting size: 730 x 1040 mm

Max. pressure: 300 Tons

Thickness of material: 0,1 - 2 mm

Die-cutting precision: ±0.1 mm

Max. feeding pile height: 1280 mm

Max. speed: 7.500 sheets / hour

Machine weight: 15.000 kg

Dimensions: Lenght 582 x Width 386,5 x Height 260 cm

Power: 16 kw

YouTube-Link: https://youtu.be/StMm3ywLfQ8 |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050, 2024 (Ref.:M6425)

Year: 2024

Price: on request

Max. cutting size: 730 x 1040 mm

Die chase inner size: 760 x 1144 mm

Cutting plate size: 736 x 1080 mm

Min. gripper length: 8 mm

Cutting precision: ±0.1 mm

Max. cutting pressure: 350 t

Max. cutting speed: 7500 sheets/hour

Pre-stacking height: 1550 mm

Delivery pile height: 1400 mm

Cardboard: 0.1-2 mm

Corrugated paper: < 4 mm

Main motor power: 11 kw

Heating area power: /

Total power: 17.8 kw

Weight: 16 t |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050Q, 2025 (Ref.:M6426)

Year: 2025

Price: on request

Max. cutting size: 730 x 1040 mm

Die chase inner size: 760 x 1144 mm

Cutting plate size: 736 x 1080 mm

Min. gripper length: 8 mm

Cutting precision: ±0.1 mm

Max. cutting pressure: 350 t

Max. cutting speed: 7500 sheets/hour

Pre-stacking height: 1550 mm

Delivery pile height: 1400 mm

Cardboard: 0.1-2 mm

Corrugated paper: < 4 mm

Main motor power: 11 kw

Heating area power: /

Total power: 17.8 kw

Weight: 18 t |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050QQ, 2024 (Ref.:M6427)

Year: 2024

Price: on request

Max. cutting size: 730 x 1040 mm

Die chase inner size: 760 x 1144 mm

Cutting plate size: 736 x 1080 mm

Min. gripper length: 8 mm

Cutting precision: ±0.1 mm

Max. cutting pressure: 350 t

Max. cutting speed: 7500 sheets/hour

Pre-stacking height: 1550 mm

Delivery pile height: 1400 mm

Cardboard: 0.1-2 mm

Corrugated paper: < 4 mm

Main motor power: 11 kw

Heating area power: /

Total power: 17.8 kw

Weight: 18 t |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050M, 2024 (Ref.:M6428)

Year: 2024

Price: on request

Max. cutting size: 730 x 1040 mm

Die chase inner size: 760 x 1144 mm

Cutting plate size: 736 x 1080 mm

Min. gripper length: 8 mm

Cutting precision: ±0.1 mm

Max. cutting pressure: 600 t

Max. cutting speed: 7500 sheets/hour

Pre-stacking height: 1550 mm

Delivery pile height: 1400 mm

Cardboard: 0.1-2 mm

Corrugated paper: < 4 mm

Main motor power: 15 kw

Heating area power: 24 kw

Total power: 50 kw

Weight: 22 t |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050MQ, 2024 (Ref.:M6429)

Year: 2024

Price: on request

Max. cutting size: 730 x 1040 mm

Die chase inner size: 760 x 1144 mm

Cutting plate size: 736 x 1080 mm

Min. gripper length: 8 mm

Cutting precision: ±0.1 mm

Max. cutting pressure: 600 t

Max. cutting speed: 7500 sheets/hour

Pre-stacking height: 1550 mm

Delivery pile height: 1400 mm

Cardboard: 0.1-2 mm

Corrugated paper: < 4 mm

Main motor power: 15 kw

Heating area power: 24 kw

Total power: 50 kw

Weight: 24 t |

|

|

Chengyuan, Fast 1050, 2022 (Ref.:M6436)

Year: 2022

Price: on request

Min. size: 400×360 mm

Max. size: 1040×730 mm

Paper Range: Cardboard80-1200g/m², corrugated=4mm

Gripper Margin: 8mm

Max.die Cutting Speed: 7500 s/h

Max.die Cutting Pressure: 300T

Total Power 23 Kw, Power 380v 50Hz, Total Weight: 16T

Dimensions: 7016×4049×2030 mm

Video link: https://www.youtube.com/watch?v=1W7EIdcv6_s |

|

|

Hang, 107-30, 1993 (Ref.:M6212)

Year: 1993 Size: 3 x 8 mm

Price: on request

Number of drill heads: 4

Drill diameter: 3-8 mm

Drill distance: 36-260 mm

Stacking height: 60 mm

Number of revolutions: 1800 / min |

|

|

Hang, 106 DT, - (Ref.:M6556)

Price: on request

• Manufacturer: Hang (Constantin Hang GmbH)

• Model: DT 106 (106 DT)

• Machine Type: Paper drilling & punching machine

• Drilling Heads: 2 spindles, fully adjustable

• Drilling Diameter Range: 3 – 20 mm (up to 14 mm standard, optional hull usage up to 20 mm)

• Table Surface: approx. 110 × 68 cm (lateral × longitudinal)

• Maximum Distance from Edge: 470 mm (forehead drilling up to 300 mm)

• Maximum Stack Height: approx. 70 mm

• Operation: Foot pedal control (electrical)

• Power Supply: Three-phase, 380–400 V

• Machine Weight: approx. 250 kg

• Condition: Good/used (verified, cleane |

|

|

|

|

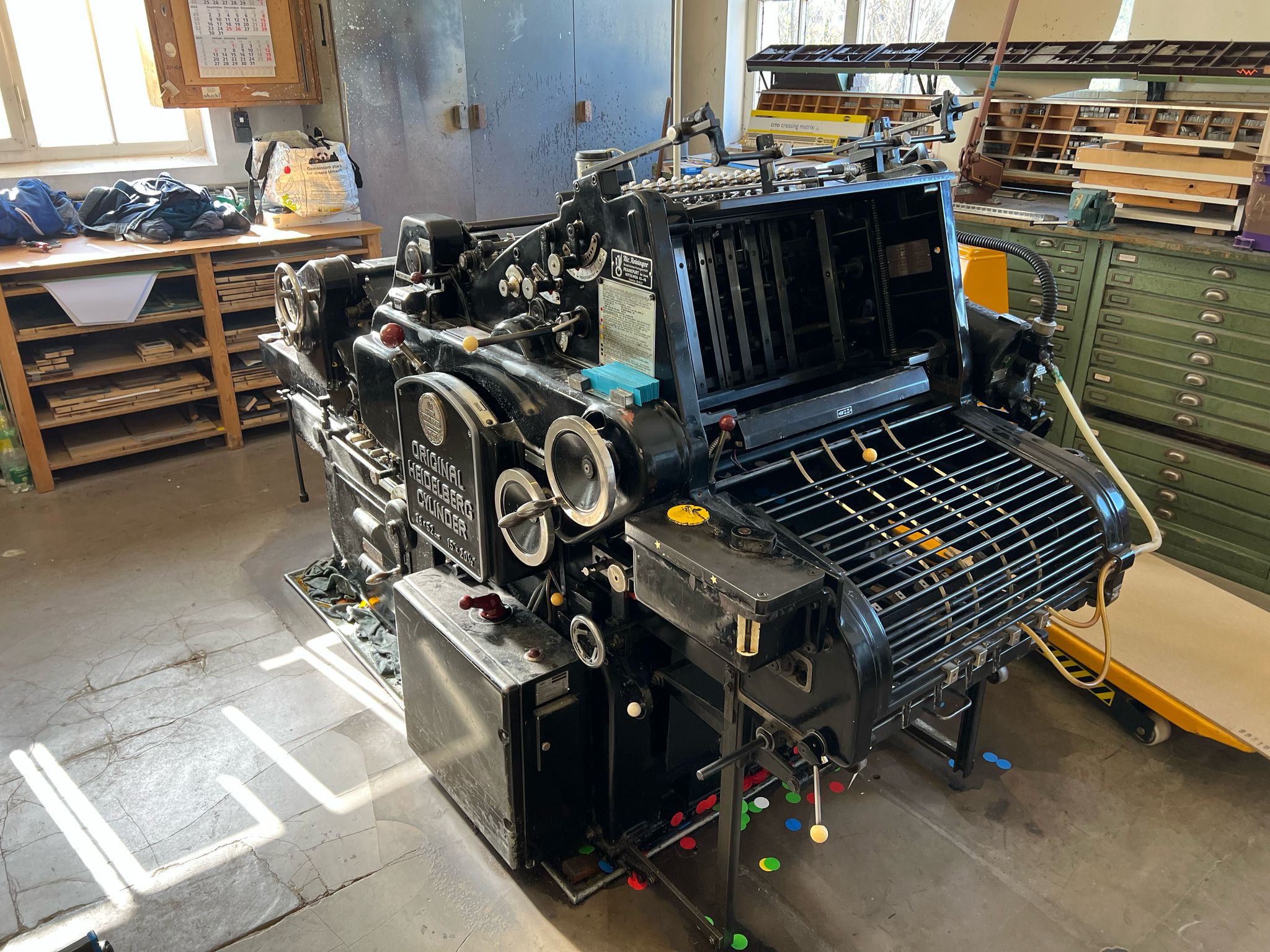

Heidelberg, SBG, 1963 (Ref.:M6648)

Year: 1963 Size: 560 x 770 mm

Price: on request

• Model: Heidelberg SBG

• Type: 1-colour letterpress

• Application: Paper converting / die-cutting and printing

• Year of manufacture: 1963

• Sheet size: 560 × 770 mm

• Condition: Standard machine

• Features: Classic and solid letterpress machine, ideal for die-cutting, embossing, and specialty

printing applications |

|

|

Heidelberg, KS, 1962 (Ref.:M6519)

Year: 1962 Size: 360 x 520 mm

Price: on request

- Letterpress printing machine

- Max. sheet size: approx. 340 x 480 mm

- Paper thickness: up to approx. 4 mm

- Speed: up to 4,000 sheets/hour

- **Platen press with swing-arm feeder**

- Precise register and strong impression force

- Suitable for numbering, die-cutting, embossing, perforating, and creasing

- Adjustable impression pressure |

|

|

|

|

|

|

|

|

Lintec, LPM 300 GT, 1997 (Ref.:M6522)

Year: 1997 Size: 300 mm

Price: on request

- **Printing process:** 6-color UV letterpress

- **Maximum material width:** 300 mm

- **Maximum printing width:** 280 mm

- **Maximum print length (repeat):** 280 x 240 mm

- **Maximum speed:** 7,200 impressions per hour

- **UV drying system:** 6 GEW UV dryers

- **Die-cutting:** 1 rotary die-cutting unit

- **Rewinder:** Integrated with slitting function (5 knives)

- **Unwinder:** With end-position sensor

- **Additional equipment:**

- Rotometrics pressure control at the

- Metal-based polymer printing plates

- 11 magnetic printing cylinders |

|

|

|

|

KMK Printing & Packaging Machinery, KMK CM-1500A (2 Reels), 2024 (Ref.:M6294)

Year: 2024 Size: 450 x 1650 mm

Price: on request

Model: KMK CM-1500A

Paper Cutting Form: The upper blade cuts backward, and the lower blade is fixed.

Paper Weight Range: 60-550g

Maximum Reel Diameter: 1800mm

Maximum Roll Width: 1500mm

Cutting Length Range: 450-1600mm

Number of Cut Sheets: 2 Pieces

Cutting Accuracy: +/- %0,1

Cutting length: >1000mm

Maximum Cutting Speed: 400 cuts/minute

Maximum Carton Stack Height: 1500 Mm

Air Pressure Requirements: 0.8 Mpa

Power Supply: 380V/220V × 50Hz

Total Machine Weight: 11,000 Kg

Full Load Power: 26 Kw |

|

|

|

|

KMK Printing packaging Maschinery, KMK XY-1060P, 2024 (Ref.:M6300)

Year: 2024 Size: 450 x 360 mm

Price: on request

KMK XY-1060 P Die-Cutting And Stripping Machine (Feeder Feeding)

Max. die-cutting speed (sheets/hour): 7500

Die-cutting precision (mm): + 0.1

Max. die-cutting pressure (t): 250

Max. paper size (mm): 1060*760

Min. paper size (mm): 450*360

Min. die-cutting size (mm): 1050*750

Paper processed

Cardboard: 80-2000 g/m2

Corrugated paper (max. thickness/mm): < 5

Total power (kW): 18

Weight (t): 16

Dimensions (L*W*H) (mm): 5950*2100*2300 |

|

|

KMK Printing packaging Maschinery, KMK XY-1300P, 2024 (Ref.:M6301)

Year: 2024 Size: 550 x 450 mm

Price: on request

KMK XY-1300 P Die-Cutting And Stripping Machine (Feeder Feeding)

Max. die-cutting speed (sheets/hour): 5000

Die-cutting precision (mm): + 0.25

Max. die-cutting pressure (t): 300

Max. paper size (mm): 1320*950

Min. paper size (mm): 550*450

Min. die-cutting size (mm): 1310*940

Paper processed

Cardboard

Corrugated paper (max. thickness/mm): < 6

Total power (kW): 18

Weight (t): 18

Dimensions (L*W*H) (mm): 7300*2300*2400 |

|

|

KMK Printing packaging Maschinery, KMK XY-1500P, 2024 (Ref.:M6302)

Year: 2024 Size: 550 x 450 mm

Price: on request

KMK XY-1500 P Die-Cutting And Stripping Machine (Feeder Feeding)

Max. die-cutting speed (sheets/hour): 4500

Die-cutting precision (mm): + 0.25

Max. die-cutting pressure (t): 300

Max. paper size (mm): 1500*1100

Min. paper size (mm): 550*450

Min. die-cutting size (mm): 1490*1090

Paper processed

Cardboard

Corrugated paper (max. thickness/mm): < 8

Total power (kW): 22

Weight (t): 20

Dimensions (L*W*H) (mm): 8400*2600*2500 |

|

|

KMK Printing & Packaging Machinery, KMK AEM-1050T, 2024 (Ref.:M6459)

Year: 2024

Price: on request

Max. paper size: 750 x 1050 mm

Min. paper size: 360 x 400 mm

Max. cutting size: 730 x 1040 mm

Die chase inner size: 760 x 1144 mm

Cutting plate size: 736 x 1080 mm

Max. foil stamping size: 720 x 1040 mm

Min. gripper length: 8 mm

Cutting precision: ±0.1 mm

Foil stamping precision: ±0.125 mm

Max. cutting pressure: 350 t

Max. cutting speed: 7500 sheets/hour

Max. foil stamping speed: 7500 sheets/ho

Max. foil roll diameter: 200~250 mm

Vertical foil roll width: 50~1060 mm

Horizontal foil roll width: 50~760 mm |

|

|

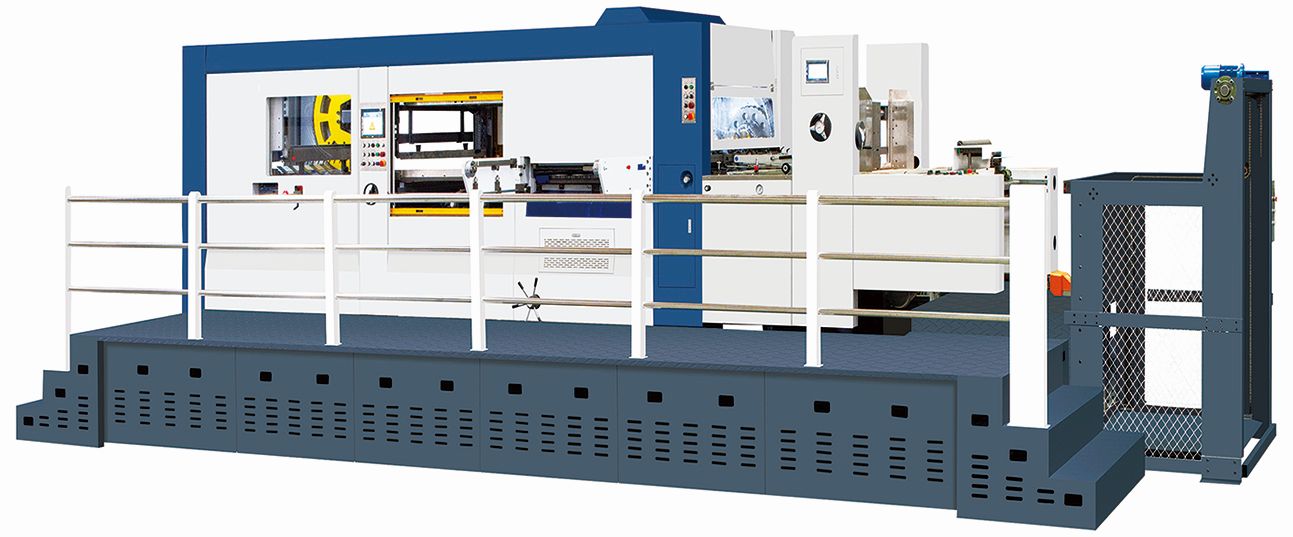

Bobst, Autoplaten SP 142, - (Ref.:M6591)

Size: 1420 x 1020

Price: on request

Manufacturer: Bobst, Switzerland

Model: SP 142

Machine Category / Maschinenart: Die Cutting Machine / Stanzmaschine

Machine Type / Maschinentyp: Autoplaten / Autoplatine

Year: --- (not specified)

Machine No.: 057400108

Technical Data:

- Max. Sheet Size: 1420 x 1020 mm

- Min. Sheet Size: 700 x 500 mm

- Speed: up to 4,500 sheets/hour (depending on series)

- Power Supply: 380 V, 50 Hz

Features:

- Robust Swiss-made construction

- Mechanical control with side operator

- Pile feeder and delivery system for co |

|

|

|

|

|

|

|

|

|

|

MKS Maschinen Handels GmbH

Lothforster Str. 46, D-41849 Wassenberg-Germany

|

|